|

|

| |

|

|

|

|

|

|

Click to enlarge image Click to enlarge image |

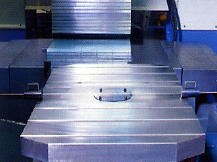

| Adopt dual table of Automatic Pallet Change system |

|

High speed 180° indxxing dual table increases productivity by reducing

during workpiece setup time by enabling workpiece loading during the machining

process on the opposite side.

- High speed : 4.7sec / 180°

- High precision : 5" / 180°

- High capccity : Max load up to 200kg x 2ea

|

|

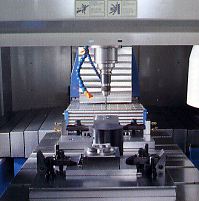

| Rapid speed synchronized TAP function |

|

For high speed & predision of tapping, position synchronized system

enabled to achieve perfect synchronized feed of main spindle & Z axis.

|

|

| Rapid speed synchronized TAP function |

|

For high speed & predision of tapping, position synchronized system

enabled to achieve perfect synchronized feed of main spindle & Z axis.

|

|

| CNC controller with high technology |

|

32bit of CNCcontroller alloes multi-display and high speed of numerical

process with easy control and repair. Especially, this work perfectly

with Factory Automation (including DNC function)and hereby increase productivity

|

|

|

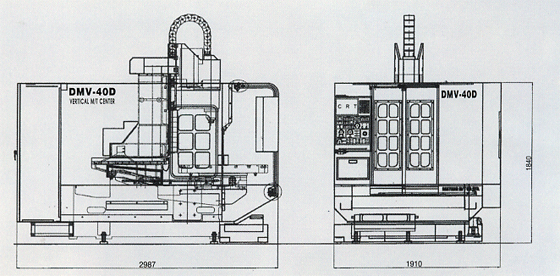

Description

|

Item

|

Unit

|

DMV-40D

|

Standard Equipments

- Coolant System

- Splash Guard

- Hydraulic Unit

- Work Light

- Work Tool

- Air UNit

- Spindle Air Blast

- Rigid Tap

- Manual

Optional Equipments

- Spindle Cooling System

- Patrol Light(2 step)

- Transformer

- Dual Table

- Auto Door

- Chip Conveyor

- Rotary Join

- Chip Bucket

- Oil Lubrication

|

|

Table

|

Table number

|

EA

|

2

|

|

Table size (WxL)

|

mm

|

600x360

|

|

Max. load capacity

|

kg

|

2x200

|

|

Travels

|

X axis

|

mm

|

500

|

|

Y axis

|

mm

|

320

|

|

z axis

|

mm

|

410

|

|

Distance from table surface to spindle

gauge plane

|

mm

|

100~530

|

|

Spindle speed

|

rpm

|

12,000

|

|

Main axis taper

|

kw

|

ISO No.40

|

|

Rapid traverse (W/Y/Z)

|

m/min

|

40/40/40

|

|

Cutting feedrate

|

m/min

|

1~10

|

|

Spindle power

|

kw(HP)

|

7.5/7.5

|

|

Traverse axis motor (X/Y/Z)

|

kw 1.4/1.4/3.5

|

|

|

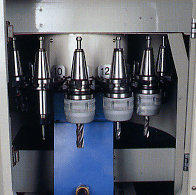

ATC

|

Type of tool shank

|

|

BT40(HSK)

|

|

Tool storage capacity

|

EA

|

16

|

|

Max. tool diameter

|

mm

|

Ø90

|

|

Tool clamp pressure

|

kg

|

600±10%

|

|

Tool change method

|

|

Armless

|

|

Tool selection method

|

|

Random

|

|

Max. tool length

|

mm

|

250

|

|

Max. tool weight

|

kg

|

4

|

|

Coolant

|

Coolant motor

|

kw

|

0.25

|

|

Power source

|

Electrical power source

|

V

|

AC220+6, -10%

|

|

Total power capacity

|

kVA

|

24

|

|

Compressed air supply

|

kg/cm2

|

5±1

|

|

CNC

|

CNC Model

|

|

FanucOi-MA

|

|

Machine

|

Machine hight

|

mm

|

2,650

|

|

Need size

|

mm

|

1,960x2,987

|

|

Machine weight

|

kg

|

4,500

|

|

The designs and specifications are subject

to change without prior notice.

|

|

|

| [ 연락처 정보 ] |

Company Company |

대양메카텍 (주) |

Address Address |

경상남도 김해시 한림면 시산리 583

(우:621-871) 한국 |

Phone Phone |

82 - 55 - 3462890 |

Fax Fax |

82 - 55 - 3462893 |

Homepage Homepage |

www.dmt.co.kr |

Contact Contact |

김윤석 / 과장 |

|

|

|

| |

|

Copyright(c) 대양메카텍(주) All Rights Reserved.

Tel : 055-346-2890 Fax : 055-346-2893

|

|

|

|

|